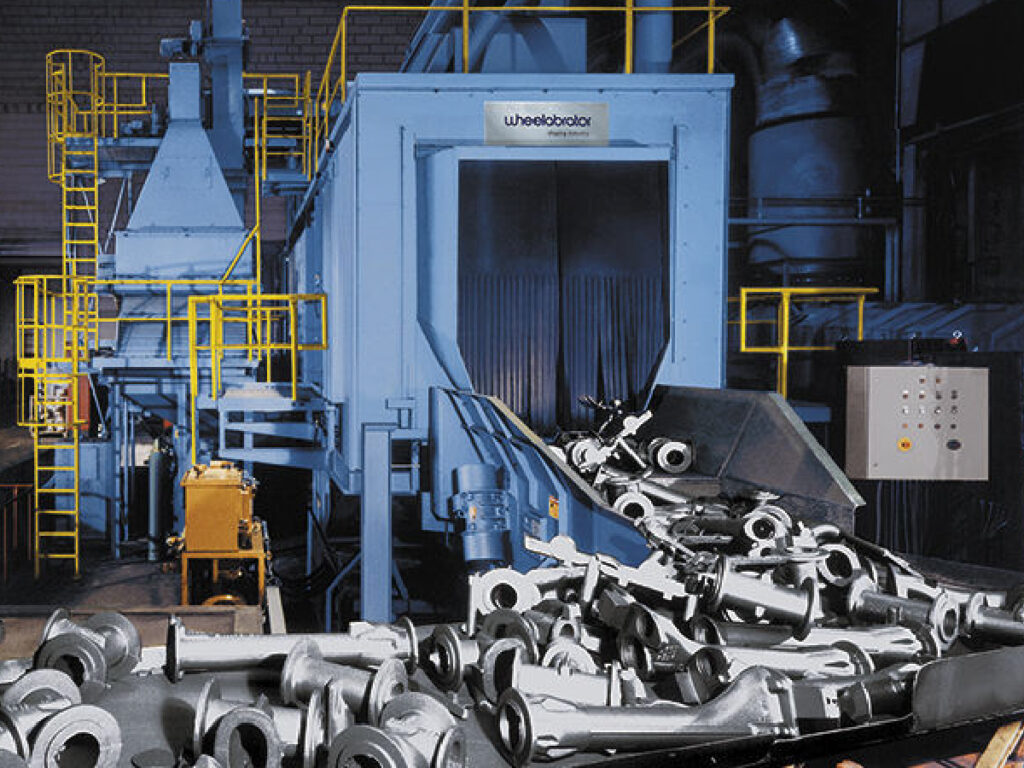

Shot blasting is a method that basically consists of throwing an abrasive (abrasive grit) at high speed against the surface to be cleaned. The action of throwing the shot is achieved by centrifugal force, through the rotation of a turbine rotating at a continuous shaft speed. The blast media bounces off the surface to be treated and returns to the hopper for further processing.

Shot blasting machines are designed in such a way that the turbine throws the abrasive at an inclined angle to the floor surface to be cleaned.

How exactly does the shot blasting process work?

- The shot is loaded into the hopper of the machine. The hopper acts as a funnel to direct the shot to the shot valve.

- The trigger valve is controlled by a cable and by a lever located where the machine operator is for easy access.

- After passing through the shot valve, the shot flow is directed to a "control zone" that will allow it to fall into the optimum position. This control zone can be calibrated (adjusted) to ensure that the shot is achieving a uniform pattern across the width of the machine.

- After passing through the control zone, the blast media is picked up by the blast wheel and travels at high speed towards the surface to be treated. Depending on the size of the machine, the blast wheel may be a one-piece unit or be composed of

of a central casing with a series of blades (vanes). - The force of the abrasive hits the floor and removes surface contaminants, leaving a clean, dry floor.

- The rebounded shot and debris then travels down the reclaim channel and ends up in a container located directly in the

above the hopper. - Once that bin is filled, the debris particles are removed by suction from the dust collector and the heavier shot is recycled back into the hopper.

- The process begins again, maintaining a continuous cycle.

- Over time, the blasting media eventually wears out and will need to be renewed by adding new particles to the hopper.

As producers of custom-made metal parts, produced by the investment casting technique, we can participate in projects of parts with very different characteristics.

Contact our team to identify the elements necessary for your custom metal parts production project to have the characteristics you are looking for for your company.