The valves serve as a mechanical element is used to regulate, allow or prevent the passage of a fluid through an industrial facility or machine of any kind. Therefore, in MetalCast it is important to achieve the necessary precision so that the metal parts work optimally within the design of the final product.

The use of pressure operated systems is a normal situation in the industry. Reactors, boilers, reheaters, storage tanks, pipelines and other pressure equipment can be subjected to pressures higher than those of design, with the consequent risk of explosion, which can cause serious consequences for both people and nearby facilities. To prevent this risk, safety valves are installed in these equipments that allow, by means of the discharge of the contained fluid, to relieve the excess pressure. Thus, safety valves are a key safety element widely used in the industry and required by regulations, so it is important to properly understand their operation and limitations.

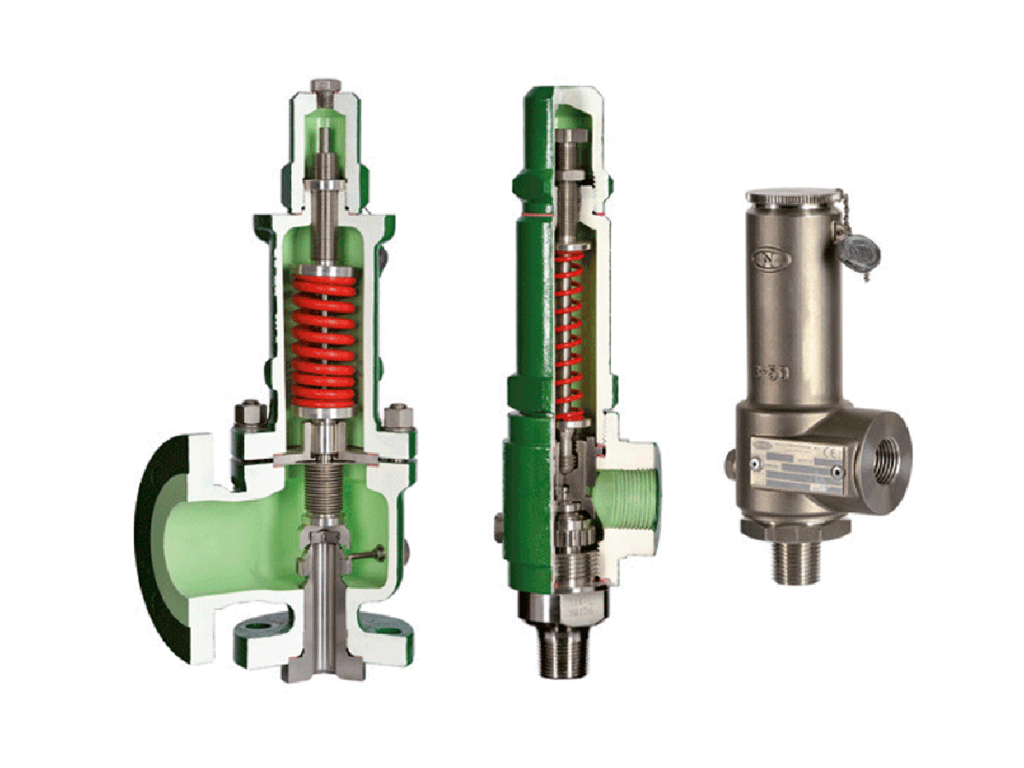

The safety valve is a device used to evacuate the necessary fluid flow so that it does not exceed the bell pressure of the protected element.

Types of safety valves

Safety valves are classified: According to their elevation

-Safety valves with instantaneous opening: When the set pressure is exceeded, the valve opens suddenly and completely.

-Pressure relief valves: When the set pressure is exceeded, the valve opens proportionally to the increase in pressure.

According to your performance

-Direct acting valves: They are axially loaded valves, which when reaching the set pressure open automatically due to the action of the pressurized fluid on the valve closure.

-Indirect acting valves: These are pilot operated valves. They must act properly without the aid of any external source of energy.

According to your grouping

-Single safety valves: These are the ones that house a single valve seat in your body.

-Double or multiple safety valves: These are the ones that house two or more valve seats in their body.

The use of pressure operated systems is a normal situation in the industry. Reactors, boilers, reheaters, storage tanks, pipelines and other pressure equipment can be subjected to pressures higher than those of design, with the consequent risk of explosion, which can cause serious consequences for both people and nearby facilities. To prevent this risk, safety valves are installed in these equipments, which allow, by means of the discharge of the contained fluid, to relieve the excess pressure. Thus, safety valves are a key safety element widely used in the industry and required by regulations, so it is important to properly understand their operation and limitations.

The use of pressure operated systems is a normal situation in the industry. Reactors, boilers, reheaters, storage tanks, pipelines and other pressure equipment can be subjected to pressures higher than those of design, with the consequent risk of explosion, which can cause serious consequences for both people and nearby facilities. To prevent this risk, safety valves are installed in these equipments, which allow, by means of the discharge of the contained fluid, to relieve the excess pressure. Thus, safety valves are a key safety element widely used in the industry and required by regulations, so it is important to properly understand their operation and limitations.

MetalCast provides manufacturing of valve parts

As producers of custom-made metal parts, produced by the investment casting technique, we can participate in projects of parts with very different characteristics.

Contact our team to identify the elements necessary for your custom metal parts production project to have the characteristics you are looking for for your company.